Production of molds to order of any complexity

A range of services for the manufacture and processing of metal products

Submit an inquiry

VPS Metall - high quality mold making at a reasonable price

VPS Metall offers all types of mold manufacturing, incl. all types of work on CNC machines. Numerical control of machine tools allows us to automate the work, and our customers receive high-precision products in a short time.

Video about us

Why you should turn to VPS Metall:

TECHNICAL DOCUMENTATION

Quick calculation of the order - on average, 2 working days (depending on the volume)

BEST QUALITY

High precision processing and use of any materials

LOW COST

Affordable prices (CNC machines allow you to reduce the amount of work, and therefore reduce the cost of services).

DISCOUNTS FOR MANUFACTURING PARTS

Discounts for mass production order.

SHIPMENT AND DELIVERY OF FINISHED PRODUCTS

We carry out delivery across all Ukraine.

CALCULATE THE PRODUCTION COST OF YOUR PART

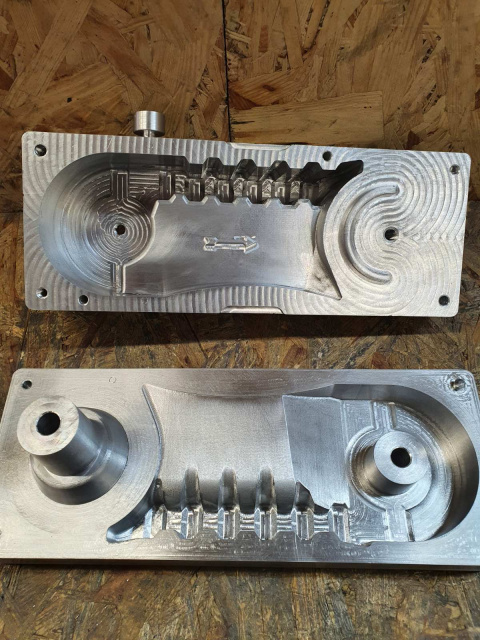

Examples of our work:

Who do we work with:

PRIVATE CUSTOMERS

We make single orders and small wholesale, and offer the production of a prototype (trial part) to a batch order

BIG ENTERPRISES

In industries: mechanical engineering, car building, metal structures, agriculture, shipbuilding, mining, etc.

STATE CUSTOMERS

We carry out about 12 large tenders monthly

VPS Metall - best mold service provider

The injection molding process of plastic or rubber products is currently the most applicable for the manufacture of various parts and components. VPS Metall has been professionally working in the metalworking market for more than 10 years, including the production of molds necessary for the manufacture of plastic parts. The technology for manufacturing products from plastic or rubber is quite simple, you only need an injection molding machine and a mold for casting:

- raw materials are melted in a thermoplastic machine;

- the resulting mass under high pressure fills the mold;

- after cooling, the finished product is removed from the mold.

In the process of manufacturing finished products, molds, dies, as well as other elements of technological equipment exposed to high pressure and temperature. From how well the production of molds was made, their service life depends.

Our company produces from high quality raw materials on modern equipment, which gives a guarantee for a long service life. Thanks to a well-established technological process, the cost of all manufactured products is quite affordable.

VPS Metall offers mold design. When developing a design, it is important to observe the exact geometric correspondence of all dimensions of the required part and take into account many other parameters:

- the number of cast elements at a time;

- efficiency of the cooling system;

- ease of extraction;

- strength;

- mold resource and more.

In order for our specialists to start designing, it is necessary to provide a drawing of the product or its finished sample. Our design and fabrication services are reasonably priced to avoid significant costs at this stage of foundry organization.

The mold making process is quite complicated and requires modern equipment. Production usually includes the following main stages:

- roughing of the workpiece using milling and electroerosive machines;

- milling of the holder, cooling channels and other elements of the mold;

- several types of heat treatment, allowing dozens of times to increase the service life of the form;

- after the final hardening, finishing milling and polishing of the parts is carried out.

Then, after completion, it is handed over and tested. If the customer wishes, the necessary adjustments are made to the design, and only after that the equipment is delivered to the address specified in the contract.

Our company manufactures molds in Dnipro using the latest equipment, while we work with clients throughout the country. Now there is nothing easier than buying a new mold. Our experienced specialists will help at all stages of production - from design right through to production. Our customers will never have to overpay, while we always guarantee high quality products.

Phone for inquiries and orders - +38 (098) 389-08-68

Our other services: Turning works, Metalworking, Milling work, Gear hobbing, Die making, Mold making, Laser cutting .